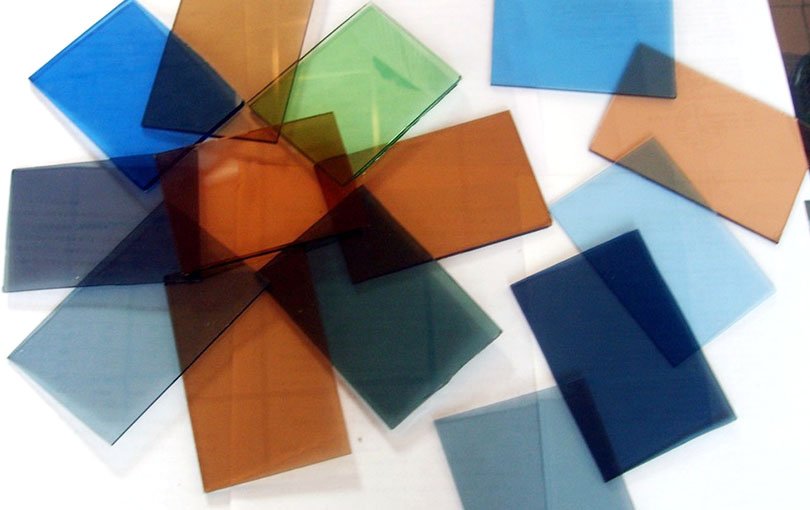

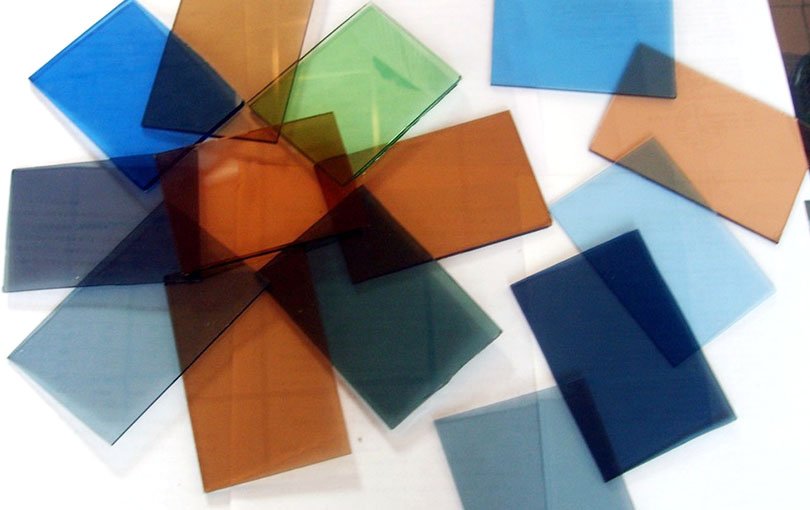

Blue Glass (Light Blue Glass – Ford Blue Glass – Lake Blue Glass – vidrio gris)

First, all the raw materials (such as silica, lime, soda ash, dolomite and feldspar) and the iron, vanadium, copper and colbalt metal elements , will be fully mixed in the batch mixer, to be prepared for the next molten process.

Second, all the raw materials will be melted in the fusion furnace under high temperature around 1550℃.

Third, the molten glass will be fed into the molten tin. The molten glass float on the flat surface and been drawn off, pulled and pushed according the required thickness.

Forth, when the thickness is well, the glass will be lifted onto the conveyor rollers and pass through the controlled cooling tunnel with more than 100 meters length.The beginning temperature of the tunnel is around 600℃, the glass will exit the annealing lehr at room temperature.

Fifth, after the temperature dropped, the glass will be cut automatically in the lengthwise and crosswise by cutter. After cutting, the glass sheets will be stacked on the racks by the vacuum lifter automatically.

Sixth, In the whole production process, the automatic inspections and manual sampling inspection can ensure the glass quality.

1 Good aesthetic effect. The blue color is similar as the sky blue and ocean blue color, if the building glass with the blue glass, then could inosculate the sky and land as a whole, which offer great flexibility to the designers.

2 Good thermal properties. The light blue glass can block and reflect different lights, which reduced the solar radiation effectively, and make the windows and doors with lower SHGC parameter, improved the glass thermal performance and Saved the energy consumption in the room.

3 The ford blue glass and lake blue glass can provide a certain privacy for the people. For the objects in the room, it can block the ultraviolet rays to slow the fading process and prolong its lifespan.

4 Good mechanical performance. The blue glass can be cut, drilled, grind, polished tempered and so on, without easily broken.

The blue glass can be used as the basal lamina to produce blue mirror, blue tempered glass, blue laminated glass, blue insulated glass, blue acid etched glass and so on. With its superior performance, the light blue glass are widely used in the windows and doors, glass roofs, facades, glass staircases, balconies, greenhouses, skylights and so on.

Glass color: Blue/Light Blue/Ocean Blue/Sky Blue/Ford Blue

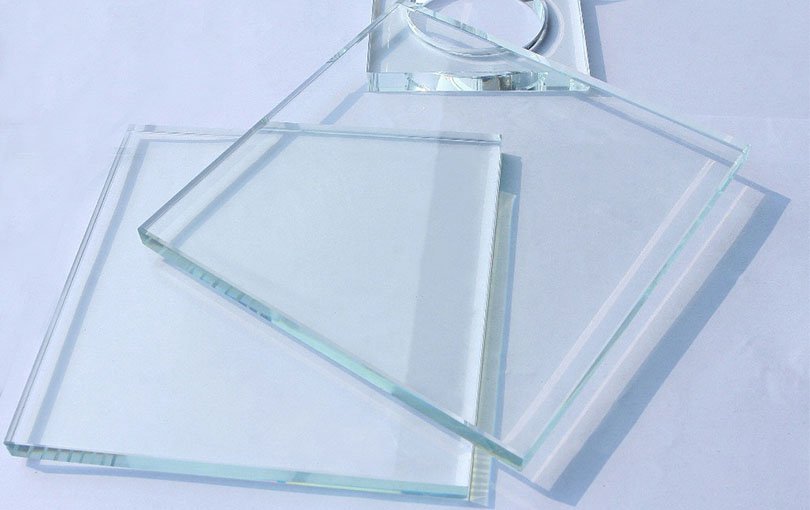

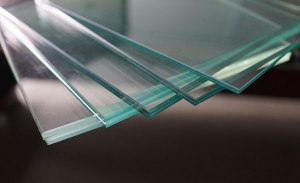

Glass Thickness: 3mm/4mm/5mm/5.5mm/6mm/8mm/10mm/12mm,etc

Glass Size:2440mm×1830mm/3300mm×2140mm/3300mm×2250mm/3300mm×2440mm/3660mm×2140mm,etc

-

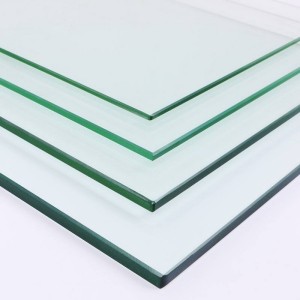

4mm Float Glass for sale with bottom price

-

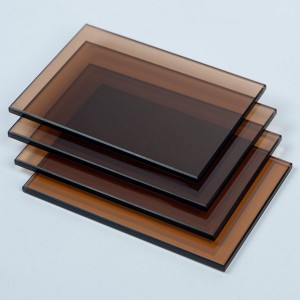

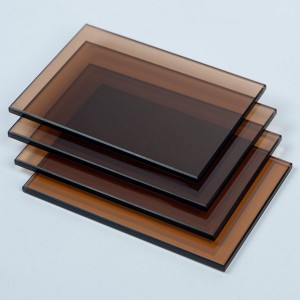

Bronze Float Glass(Vidrio Bronce,cristal bronce)

-

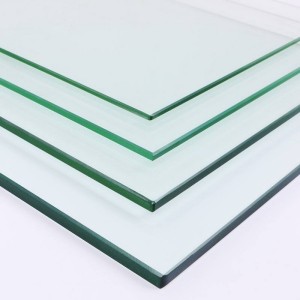

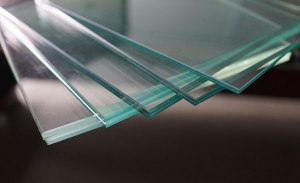

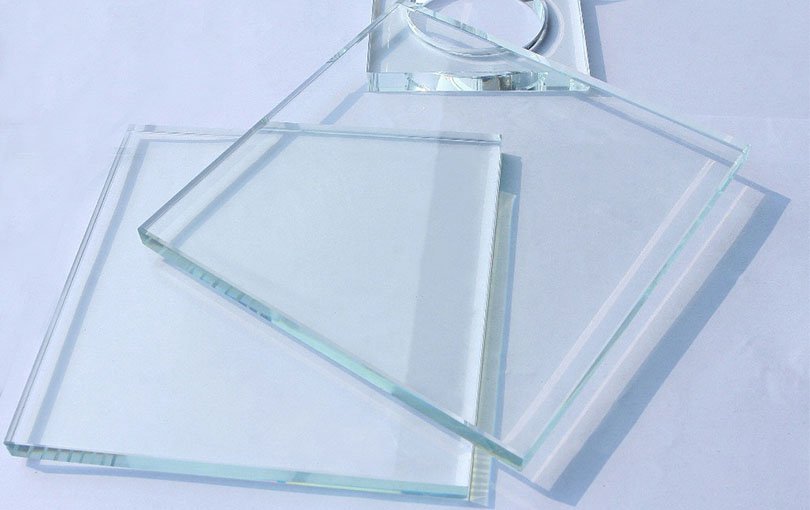

Clear float glass,transparent glass, annealed g...

-

Ultra clear float glass,low iron glass, extra c...

-

Tinted glass with bronze, grey, green, blue, pi...

-

reflective glass, bronze reflective glass, grey...

-

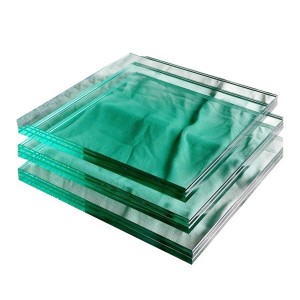

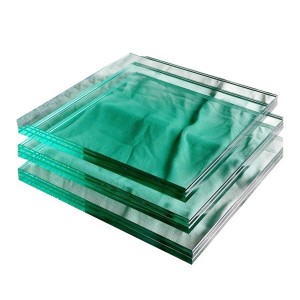

6.38mm Laminated Glass for windows and doors

-

Laminated glass, security glass,partition glass...

-

Laminated Tempered Glass or tempered laminated ...