HST Glass (heat soaked glass) and heat soak test

The first stage is the temperature raising process. Started from the ambient temperature which the toughened glass located in, finished when the temperature for all the toughened glass surface is around 280℃,the heating rate should be lower than 1.5℃/min. The temperature in the heat soaked oven maybe be higher than 320℃. To keep the temperature on the tempered glass surface below 320℃,and shorten the time of the surface temperature is higher than 300℃.

The second stage is heat preservation. When all the tempered glass surface temperature reach 280℃, then the heat preservation started. In this stage, the temperature for the tempered glass surface should be kept around 290℃±10℃, and it will last 2 hours.

The third stage is cooling. When the last tempered glass piece which surface temperature reach 280℃, have been in the heat preservation process for two hours, this stage started. When the temperature in the heat soaked oven reach 70℃, this cooling process could be stopped. In this cooling process, the cooling rate should be controlled, to minimize the damage from the thermal stress to the tempered glass.

1 The Spontaneous explosion rate in the using is reduced greatly. Through expanding the NIS crystal under high temperature in the oven, could make the tempered glass explosion in advance, reduced the Spontaneous explosion and provide good safety.

2 Good security performance. According the statistical data in the few past years, the tempered glass with normal specifications after heat soaked test, its Spontaneous explosion rate lower than 0.1% could be guaranteed. Compared to the 0.5% Spontaneous explosion rate of toughened glass without heat soaked test, it is much lower. This could provide high security for users.

3 Higher cost for the HST glass. As the heat soaked oven is powered by electricity, and the heat soak process need more than 5~6 hours, the space in the oven is limited, so the cost to get the heat soaked tempered glass is higher.

1 Even the Spontaneous explosion rate is reduced greatly after heat soaked test, but it not means there is no Spontaneous explosion for the tempered glass during the using. Now no factory could promise to avoid the Spontaneous explosion 100% after heat soaked test.

2 Some insincere factories charge you for the heat soaked test, but they don’t make it for you. So it’s better to choose the reliable factory such as Nobler Glass, you could arrange people to supervise the heat soaked test in our workshop, and we also offer the real-time online supervision by video to guarantee the process, meet the standard EN14179-1:2005.

The heat soaked toughened glass can be used in a wide range of applications, especially for the place where need lower Spontaneous explosion rate of glass, such as high curtain walls, commercial buildings, windows and doors, skylights, partitions, handrails, overhead glazing, etc.

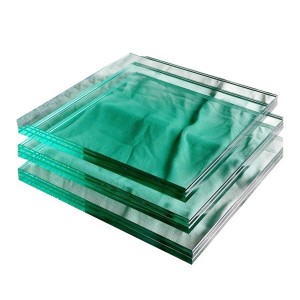

Glass color: Clear/Ultra Clear/Bronze/Dark Bronze/Euro Grey/Dark Grey/French Green/Dark Green/Ocean Blue/Ford Blue/Dark Blue,etc

Glass Thickness: 3mm/4mm/5mm/6mm/8mm/10mm/12mm/15mm/19mm,etc

Glass size: According request, Maximum size could reach to 5000mm×2500mm